PVC (polyvinyl chloride) roofing is robust, reliable, and durable. También es altamente reflectante y 100% reciclable, lo que contribuye a la sostenibilidad y a la reducción de los gastos de energía. Si bien los techos de PVC tienen muchas ventajas, no todas las membranas de PVC son iguales. Muchas de las diferencias se reducen a la colocación de la malla y al refuerzo de la membrana. Descubra las ventajas del PVC y por qué algunas membranas de PVC pueden ser más confiables que otras.

PVC Offers a Strong History

The two primary reasons to specify a PVC roof are resilience and sustainability. PVC roofs offer unparalleled chemical and fire resistance, making them popular for schools, restaurants, manufacturing facilities, airports, buildings in industrial zones, and other commercial properties exposed to destructive agents. PVC flat roofs have a long history in North America, with the first roof installations being made in the 1970s. This material has performed exceptionally well against UV damage, harsh chemicals, fire, and hurricane-level winds.

For example, the National Hurricane Center of the National Oceanic and Atmospheric Administration in Miami installed a PVC roof only weeks before Hurricane Matthew hit Florida in 2016. The Chemical Fabrics and Film Association reports that the roof sustained no damage and "performed just as well in subsequent storms, including Irma, a Category 4 hurricane that made landfall carrying sustained winds of up to 112 miles per hour."

Cool roofs are growing in popularity, and some U.S. cities and states mandate their use to help combat climate change. PVC single-ply membranes are an excellent solution to improve a building's energy efficiency and sustainability when you need to specify a highly resilient roofing system.

That said, only the highest quality PVC membranes can be expected to deliver the highest quality results.

What Makes a "Good" PVC Membrane?

Are all PVC membranes equal? Simply put, no. Not all PVC membranes are the exact same. There can be a significant difference in performance and resilience between various PVC manufacturers, depending on the membrane design, material choice, and quality assurance during production.

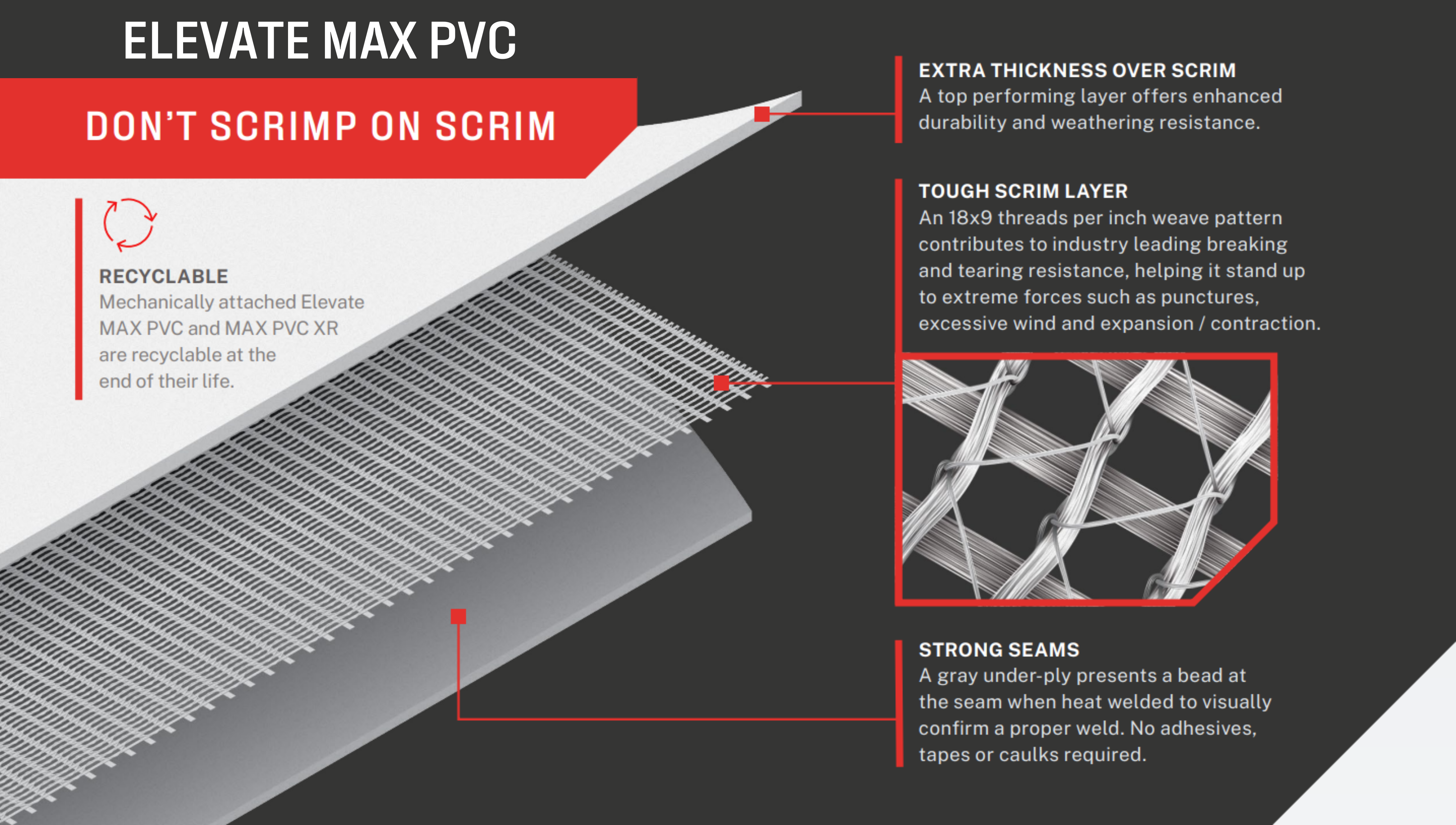

There are several critical elements of a PVC membrane, but some of the most important are the scrim layer, and the top and bottom layers of the membrane.

The Scrim: What It Is and Why It's So Crucial

The scrim layer is located between the top and bottom layers of a PVC single-ply membrane. It's sandwiched between the two and provides the necessary reinforcement for adequate dimensional stability, tear resistance, physical properties, and wind uplift performance. Without scrim, the performance of a PVC membrane would be dramatically reduced, and thus the overall performance of the roof could be reduced, too.

Since scrim is so crucial, its application differences can have a substantial positive or negative effect on membrane resilience. In other words, the scrim's position in the membrane and design can potentially determine the reliability and ultimate longevity of a PVC roof.

Scrim can be made from intertwined polyester or fiberglass, but polyester offers higher puncture resistance, tearing strength, and dimensional stability. The higher the number of threads, the stronger the roofing scrim.

High-quality PVC membranes have the scrim positioned in the middle of the membrane. In addition, premium PVC single-ply systems utilize a weft-inserted knitting technology that prevents runs and spreading of tears. A weft insert keeps the yarns locked to one another. So, if any cracks occur, they are less likely to spread, making roof repairs easier and quicker.

Impact of Top Layer Thickness on PVC Membrane Longevity and Effectiveness

While it's generally accepted that the higher thickness membranes are more resilient, that's only true if the top layer of the membrane has sufficient thickness. A membrane with a 20 mil top layer is less likely to outlive a membrane with a 30 mil top side.

The ASTM D 4434 standard specifies many crucial properties of PVC roof membranes, including the thickness over scrim. This standard defines a minimum thickness over scrim of 16 mils per test method ASTM D 7635. All Elevate PVC membranes significantly exceed the minimum thickness over scrim. For example, the 60 mil Elevate MAX PVC membrane has a thickness over scrim of 31 mils, nearly double the required value.

The top layer contains the stabilizers and other vital components needed for protection from ultraviolet, heat, and harsh weather. The top layer is crucial to PVC performance. The higher the thickness over scrim, the longer the membrane should typically last.

Premium PVC membranes have sufficient top layer thickness with significantly higher thickness over scrim than the ASTM D 4434 specifies. All Elevate PVC single-ply roofing systems exceed ASTM D 4434 specifications by a large margin, providing a long-term, resilient, and sustainable solution for maximum performance and reliability you can count on.

Introducing Elevate MAX PVC

Specify Elevate MAX PVC and MAX PVC XR for roofing systems that need to endure harsh conditions such as chemicals and grease. Low-maintenance, extremely durable, and reflective, Elevate MAX PVC is a sustainable solution for roofs exposed to environmental contaminants and extreme weather.

Elevate MAX PVC has an exceptional thickness over scrim, and a tough scrim layer composed of 18x9 threads per inch. As a result, it provides industry-leading resistance to punctures, breaking, and tearing. Elevate MAX PVC offers building owners peace of mind with its high durability and the Elevate Red Shield Warranty is available for up to 30 years when installed by a licensed Red Shield applicator.

Elevate Your Roof's Performance With Premium PVC Roofing Systems

Learn more about Elevate PVC roofing materials and contact Elevate to place your order for MAX PVC today. Need help determining if PVC is the best roof material for your commercial roof? Browse our PVC product offerings and learn more about our comprehensive PVC portfolio, including our custom blend of PVC KEE, which also provides extreme versatility and durability.

For a hands-on approach, use our three-question roof explorer tool to understand the different options, which can help make a decision best suited for your project in just a few clicks. For any additional questions, please reach out to your local Elevate Sales Representative.

With industry-leading warranties, licensed Elevate applicators, exceptional PVC performance, and a wide array of PVC membranes, Elevate can meet your needs regardless of building and existing roof type.