(Rev. de febrero de 2025)*

Elevate recomienda el uso de procedimientos de aplicación en climas fríos cuando las condiciones ambientales y del sustrato caen por debajo de 40 °F (4 °C). Consulte las Hojas de información técnica (TIS) correspondientes para conocer las recomendaciones específicas de almacenamiento, manipulación y aplicación.

ADHESIVOS, SELLADORES, IMPRIMADORES Y RECUBRIMIENTOS

ALMACENAMIENTO

- Almacene todos los adhesivos, selladores e imprimadores entre 60 °F (16 °C) y 80 °F (27 °C) hasta justo antes de la aplicación para garantizar la correcta mezcla y dispensación de los productos, y para promover las tasas de aplicación adecuadas.

- Si las propiedades y las características de aplicación de los materiales comienzan a cambiar durante la aplicación en clima frío, restáurelos a temperatura ambiente antes de continuar. Los materiales almacenados a menos de 60 °F (16 °C) deben llevarse a temperatura ambiente, mezclarse completamente y examinarse para verificar la consistencia adecuada (sin marchitamiento o separación de componentes) antes de la aplicación. NOTA: Nunca mezcle el adhesivo de unión sin solventes EPDM.

MEZCLA Y DISPENSACIÓN

Cuando los materiales líquidos están fríos, su viscosidad aumenta, lo que puede hacer que los solventes y sólidos se separen. Esta separación puede dificultar la mezcla y el dispensado. Para minimizar la posibilidad de que los materiales se enfríen en el techo antes de la aplicación, siga estas pautas adicionales:

- Solo lleve los materiales del almacenamiento en caliente al techo de 1 a 4 horas antes de la aplicación, o según sea necesario para garantizar que los materiales estén cerca de 60 °F (16 °C) cuando se dispensen.

- Siempre mezcle bien los adhesivos, imprimadores y recubrimientos hasta lograr un estado suave y uniforme antes y durante el uso. Siga las instrucciones de mezclado proporcionadas con cada producto. No utilice equipos de mezclado que puedan generar una chispa, lo que podría encender material inflamable.

- En condiciones extremas, puede ser necesario durante la aplicación rotar el material entre una caja caliente o un área de almacenamiento caliente y el techo para mantener la temperatura de aplicación adecuada.

APLICACIÓN

- Los tiempos de secado dependen de las condiciones ambientales. Las condiciones frías y nubladas prolongan los tiempos de apertura (“tiempos de adherencia”), mientras que las condiciones soleadas y secas acortan los tiempos de apertura. Espere y planifique tiempos de apertura más largos en clima frío antes de adherir el aislamiento o la membrana.

- Siga todos los requisitos locales de gestión de la calidad del aire al instalar productos que contengan compuestos orgánicos volátiles (COV).

TARIFAS DE EVAPORACIÓN DE SOLVENTES

La tabla a continuación muestra varios tiempos de evaporación asociados con los componentes solventes de adhesivos, selladores, recubrimientos y revestimientos Elevate. Nuestros productos pueden contener uno o más de los solventes que se enumeran a continuación. Dado que las proporciones de solvente en cada producto varían, no se puede asignar un tiempo de evaporación definitivo a cada producto. Consulte la SDS (hoja de datos de seguridad) del producto específico para ver los componentes químicos; y compare esa información con la tabla a continuación para obtener una indicación de la eficiencia de evaporación relativa. Las condiciones ambientales tendrán una influencia en los tiempos de evaporación, pero los efectos son proporcionales.

| Solvente | Exención de VOC | Tasa de evaporación* | Intermitencia relativa |

|---|---|---|---|

| Agua | Exento de VOC | 0.3 | Extremadamente lento |

| PCBTF | Exento de VOC | 0.9 | Lenta |

| Nafta | No exento de COV | 1.4 | Mediano |

| Tolueno | No exento de COV | 2.2 | Mediano |

| TBAC | Exento de COV (excepto para los distritos de calidad del aire de CA correspondientes) | 2.8 | Mediano |

| Acetona | Exento de VOC | 5.6 | Rápido |

| Hexano | No exento de COV | 8.3 | Extremadamente rápido |

*La referencia estándar para la tasa de evaporación es acetato de n-butilo con una tasa de evaporación de 1.0.

“RUBOR” ADHESIVO (CONDENSACIÓN)

- El rubor se produce cuando el enfriamiento por evaporación del material durante el tiempo de secado disminuye la temperatura de la superficie en el punto de rocío o por debajo de este, lo que provoca condensación en las películas adhesivas y de imprimación. Esta condensación evita la adhesión adecuada. Suspenda la aplicación inmediatamente si se produce rubor.

- El uso de adhesivos e imprimadores debe monitorearse atentamente para detectar rubor cuando la temperatura ambiente está cerca del punto de rocío. La diferencia entre la temperatura ambiente y el punto de rocío suele ser menor a primera hora de la mañana y a última hora de la tarde, por lo que el mediodía suele ser el mejor momento para usar adhesivos y recubrimientos cuando se aplican productos Elevate en condiciones de clima frío. Una mayor exposición a la luz solar en cualquier momento del día disminuye el riesgo de decoloración.

ADHESIVO DE UNIÓN SIN SOLVENTE EPDM (SFBA)

- Almacene los recipientes de SFBA a temperaturas entre 60 °F y 80 °F (16 °C y 27 °C) hasta que estén listos para usar. NO permita que el producto se congele.

- Utilice el SFBA únicamente cuando las temperaturas ambiente y del sustrato excedan 40 los °F (4 °C). Si el SFBA está expuesto a temperaturas inferiores a 40 °F (4 °C), restaure el producto a temperatura ambiente antes de usarlo. No lo utilice cuando se espera que las temperaturas caigan por debajo del punto de congelación dentro de las 12 horas posteriores a la aplicación.

- No mezcle ni agite el SFBA antesde la instalación. Retire cualquier capa de piel que pueda desarrollarse en el recipiente para exponer el adhesivo nuevo para su aplicación.

- Realice pruebas de “empuje táctil” en áreas con la aplicación más pesada de SFBA y use la presión adecuada para verificar que se haya producido suficiente tiempo de apertura para iniciar el curado del adhesivo. En comparación con el adhesivo de unión EPDM estándar, el SFBA debe ser ligeramente más fácil de presionar con el dedo cuando esté listo para unirse a la membrana.

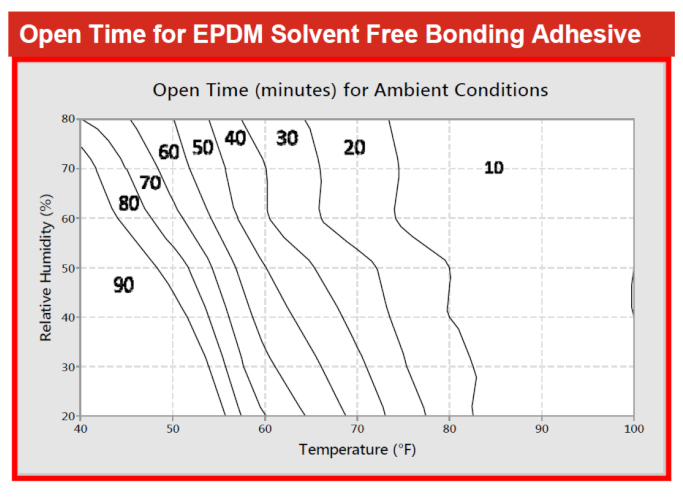

- Aunque el SFBA no contiene solventes, el adhesivo debe lograr su tiempo de apertura óptimo para la configuración antes de adherirse a la membrana del techo. Consulte la tabla a continuación para conocer los tiempos de apertura aproximados para el SFBA cuando se conocen la humedad y la temperatura ambiente relativas.

ADHESIVO AISLANTE I. S. O. STICK™ (GRADO PARA INVIERNO)

- Considerar el uso del adhesivo aislante I. S. O. Stick Winter Grade en lugar de otros adhesivos aislantes durante climas fríos si la especificación del proyecto lo permite. La fórmula de grado de invierno puede utilizarse cuando las temperaturas ambiente y del sustrato oscilan entre 25 °F y 65 °F (-3 °C a 18 °C).

- Almacene I. S. O. Stick Winter Grade entre 60 °F y 80 °F (16 °C a 27 °C) hasta justo antes de usar. Consulte en TIS 837 los requisitos completos de almacenamiento y manipulación.

- Las consistencias de los adhesivos y selladores se espesan a medida que bajan las temperaturas. Para minimizar esta consecuencia:

- Complete las áreas de prueba para determinar si las condiciones causarán problemas como condensación con la aplicación de los materiales.

- Interrumpa la aplicación cuando el material se vuelva demasiado grueso para aplicarlo correctamente.

- Si se utiliza el adhesivo de unión a base de agua Elevate de PVC, las temperaturas ambiente y del sustrato deben ser de al menos 50 °F (10 °C) y aumentar durante la aplicación y permanecer a esta temperatura durante 48 horas después. Espere tiempos de secado más largos durante temperaturas más bajas o humedad más alta.

- El adhesivo en aerosol de PVC Jet Bond se puede utilizar a 35 °F (1.6 °C) y en aumento. NOTA: El adhesivo en aerosol de PVC Jet Bond se puede utilizar ÚNICAMENTE con las membranas de PVC Elevate y PVC Elevate MAX. El adhesivo en aerosol de PVC Jet Bond no es compatible con las membranas Elevate PVC KEE o Elevate XR.

BARRERAS Y CONTRAPISOS

BARRERAS DE VAPOR

- La membrana de barrera de vapor V-Force™ puede aplicarse cuando el sustrato y las temperaturas ambiente son de 25 °F (-4 °C) o más, siempre que la V-Force se haya almacenado entre 50 °F y 100 °F (10 °C y 38 °C) antes de la aplicación.

- Consulte el TIS del imprimador previsto para conocer las instrucciones de almacenamiento y aplicación, y las limitaciones, si corresponde. INSTALACIÓN UltraPly™ TPO y FIRESTONE PVC

COMPLEMENTOS

- Los contrapisos deben almacenarse fuera del clima en un área limpia y seca en el empaque original sin abrir.

- CLAD-GARD R™ tiene una temperatura mínima de 40 °F (4 °C) al momento de la aplicación.

- CLAD-GARD SA tiene una temperatura mínima de 40 °F (4 °C) o 50 °F (10 °C) al momento de la aplicación, según la región (norte o sur).

APLICACIÓN DE MEMBRANAS Y TAPAJUNTAS PARA TECHOS

PREPARACIÓN DE LA MEMBRANA

- Almacene las membranas del techo en un lugar limpio y seco, lejos de la luz solar directa y de fuentes de perforaciones u otros daños físicos.

- Antes de la instalación, desenrolle las membranas y deje que se relajen durante 30 a 60 minutos.

- Los paneles de membrana plegados se vuelven más difíciles de relajar e instalar en clima frío, especialmente con sistemas adheridos. Se recomienda enfáticamente el uso de paneles sin pliegue en clima frío.

UltraPly™ TPO, ELEVATE PVC, ELEVATE PVC KEE y ELEVATE MAX PVC INSTALACIÓN

- Las membranas termoplásticas se vuelven más rígidas en temperaturas frías. Para ayudar a que las membranas se relajen, al principio del día de la instalación, retire la envoltura exterior y deje el rollo bajo la luz solar el mayor tiempo posible. Esto permitirá que la capa inferior más oscura de la membrana absorba la mayor cantidad de calor posible y aumente la flexibilidad de la membrana.

- Para garantizar que las uniones estén soldadas correctamente, es fundamental que se completen las soldaduras de prueba:

- En el inicio diario

- Cuando cambian las condiciones ambientales

- Cuando la soldadura se detiene durante un período significativo (p. ej., recesos para almorzar)

- Al utilizar una soldadora manual, las soldaduras de prueba deben realizarse en la membrana de desecho o en el material de tapajuntas sin soporte para garantizar que el operador esté utilizando la técnica y el ajuste de temperatura adecuados.

ADHESIVO EN AEROSOL JET BOND

- El adhesivo en aerosol Jet Bond debe almacenarse para mantener la temperatura deseada del producto a 70 °F (21 °C).

- Aplique solo cuando las temperaturas ambiente y del sustrato sean de 25 °F (-4 °C) y estén en aumento.

- No aplique cuando las velocidades del viento sean de 15 mph o más.

ADHESIVOS EN AEROSOL DE DOBLE CHORRO Y DOBLE CHORRO

- Use Elevate Twin Jet (TIS 836A) solo cuando las temperaturas ambiente y del sustrato sean de al menos 40 °F (4 °C) y estén en aumento. Mantenga los recipientes y el equipo de pulverización de Twin Jet al menos 60 °F (16 °C) hasta justo antes de usarlos.

- Se puede utilizar Elevate Twin Jet Y (TIS 836B) cuando las temperaturas ambiente y del sustrato sean de al menos 30 °F (-1 °C) y estén en aumento. Mantenga los recipientes Twin Jet Y y el equipo de pulverización al menos 70 °F (16 °C) hasta justo antes de usarlos.

- No aplique Twin Jet o Twin Jet Y cuando las velocidades del viento sean de 15 mph o más.

I.S.O. TWIN PACK™ y I.S.O. SPRAY™ R

- I.S.O. Twin Pack y I.S.O. Spray R deben almacenarse para mantener la temperatura deseada del producto entre 60 °F (16 °C) y 80 °F (27 °C).

- Aplique I.S.O. Twin Pack solo cuando las temperaturas ambiente y del sustrato sean de 20 °F (-7 °C) y estén en aumento.

- Aplique I.S.O. SPRAY R solo cuando las temperaturas ambiente y del sustrato sean de 25 °F (-4 °C) y estén en aumento.

- No intente aplicarlo en condiciones desfavorables.

INSTALACIÓN DE RUBBERGARD™ EPDM SA y ULTRAPLY TPO SA

- Almacene EPDM SA y TPO SA en un lugar limpio y seco, y manténgalos secos antes de la instalación.

- EPDM SA y TPO SA pueden instalarse cuando las temperaturas ambiente y del sustrato superan los 20 °F (-7 °C).

- Siempre observe las pautas para climas fríos cuando aplique imprimadores.

APLICACIONES DE INVISIWELD™ (ULTRAPLY TPO, ELEVATE PVC, ELEVATE PVC KEE Y ELEVATE PVC MÁX.)

- La temperatura de aplicación mínima segura para la soldadura por inducción de las membranas termoplásticas Elevate a platos InvisiWeld o InvisiWeld-S es de 0 °F (-18 °C).

- Antes de soldar por inducción con la herramienta adecuada, asegúrese de que no haya humedad o condensación en la superficie superior de la placa o en la superficie inferior de la membrana del techo. La humedad afectará la capacidad de la herramienta de inducción para soldar y puede provocar soldaduras parciales o incompletas.

- Siempre siga las pautas del fabricante de la herramienta de inducción para la calibración y el uso de la herramienta en temperaturas frías. En general, la herramienta debe calibrarse regularmente, en tiempo real, EN EL LUGAR, utilizando materiales (membrana y placas) en las mismas condiciones de temperatura que los materiales del lugar de trabajo.

INSTALACIÓN DE TAPAJUNTAS EPDM

- Los productos de tapajuntas EPDM no curados (tanto estándar como RubberGard EcoWhite™ EPDM) están diseñados para ser moldeables, pero el clima frío puede requerir calentamiento suplementario con una pistola de calor.

- Las condiciones ambientales (luz solar, viento y temperatura) y el color del tapajuntas determinarán la necesidad de calor suplementario. Por lo general, las temperaturas inferiores a 60 °F (16 °C) pueden requerir el uso de calor adicional para garantizar la formabilidad de los productos de tapajuntas sin curar.

- Mantenga las pistolas de calor y otras fuentes de ignición potenciales lejos de limpiadores, imprimadores, adhesivos u otros materiales inflamables.

ADHESIVO FRÍO MULTIUSO MB Y CEMENTO TAPAJUNTAS

- Almacene el adhesivo frío multipropósito MB y el cemento tapajuntas multipropósito MB entre 60 °F y 80 °F (16 °C y 27 °C) en sus envases originales sin abrir.

- El adhesivo frío Multi-Purpose MB se aplica mejor en climas fríos mediante el uso de una plataforma de pulverización calentada. No se recomienda el adhesivo frío aplicado con escurridor en climas fríos. Las temperaturas ambiente y del sustrato deben ser 40 de °F (4 °C) y aumentar en el momento de la aplicación.

- El cemento para vierteaguas Elevate Multi-Purpose MB solo debe usarse cuando las temperaturas ambiente y del sustrato son superiores a 40 °F (4 °C) y van en aumento.

INSTALACIÓN DE SBS, APP y BUR

- Almacene los rollos de betún modificado con SBS y APP y los fieltros de capa BUR entre 50 °F y 100 °F (10 °C y 38 °C) e instálelos cuando las temperaturas ambiente y del sustrato sean 40 °F (4 °C) y aumenten. Intentar instalar productos a base de asfalto por debajo de 40 °F (4 °C) puede reducir la adhesión, lo que resulta en deslaminado o formación de ampollas durante los ciclos de calentamiento posteriores.

- Los materiales deben utilizarse dentro de las 4 horas de su retiro de un área de almacenamiento calentada. Los materiales que no se utilicen dentro de las 4 horas deben devolverse a un área de almacenamiento calentada hasta que regresen a una temperatura entre 50 °F y 100 °F (10 °C y 38 °C), que generalmente tarda 24 horas.

- Asfalto caliente

- Los sustratos fríos pueden enfriar rápidamente el asfalto trapeado. El asfalto se enfría y espesa más rápidamente a bajas temperaturas, lo que puede hacer que las tasas de aplicación sean menos uniformes.

- Todos los equipos de manipulación deben aislarse para minimizar las caídas en la temperatura del asfalto antes de la aplicación.

- La temperatura del asfalto debe estar dentro de la temperatura equivalente publicada (EVT) pero no menos de 420 °F (216 °C) y debe mantenerse en el punto de aplicación de la membrana del techo).

- El cable del trapeador no debe estar a más de cinco (5) pies (1.5 m) del rollo.

- Enrolle las láminas de tapa en asfalto caliente con presión positiva, asegurándose de que el ancho del regazo lateral y final sea el adecuado.

- Detenga la operación y/o cambie a otro recipiente cuando no se pueda mantener la temperatura de asfalto en el punto de aplicación dentro de la EVT publicada.

- Nunca sobrecaliente el asfalto para compensar las condiciones climáticas frías y nunca caliente el asfalto por encima de su EVT o su punto de inflamación. Siempre permanezca dentro del rango de aplicación aprobado por el fabricante del asfalto, pero nunca por debajo de 420 °F (216 °C).

- Siga siempre las regulaciones de seguridad de OSHA y NRCA.

MEMBRANA Y TAPAJUNTAS DE APLICACIÓN LÍQUIDA AC FAST FR PMMA

- La PMMA Elevate AC Fast FR debe almacenarse entre 50 °F y 80 °F (10 °C y 27 °C) en un entorno controlado para facilitar la mezcla y la saturación del vellón. Para un mejor uso, 24 horas antes de la aplicación, el material debe aclimatarse a temperaturas entre 65 °F y 70 °F (18 °C y 21 °C). NO almacene los materiales al aire libre en clima frío, ya que los materiales enfriados serán difíciles de mezclar y aplicar debido a su consistencia espesa.

- No intente mezclar ni aplicar a menos que las temperaturas ambiente y del sustrato estén al menos 35 °F (2 °C) y en aumento, y los materiales se hayan almacenado correctamente hasta justo antes de su uso. La cantidad requerida de polvo catalizador AC y los tiempos de curado dependen de la temperatura ambiente. Siga atentamente las instrucciones de mezcla.

Para obtener más información o asistencia, comuníquese con Servicios técnicos de Elevate al 800-428- 4511.

* Se agregaron membranas de PVC Elevate MAX, Twin Jet y adhesivos en aerosol Twin Jet Y.